Automated tape laying toolkits

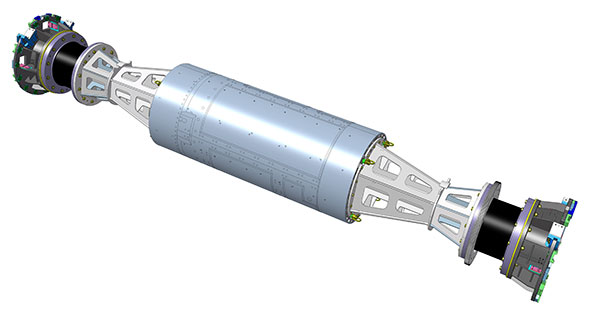

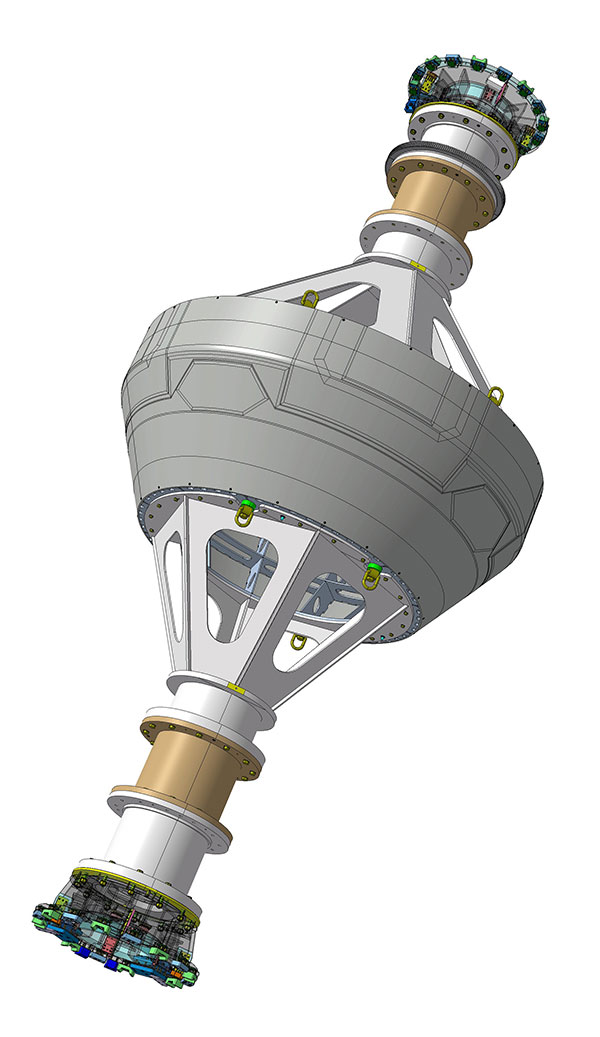

Description

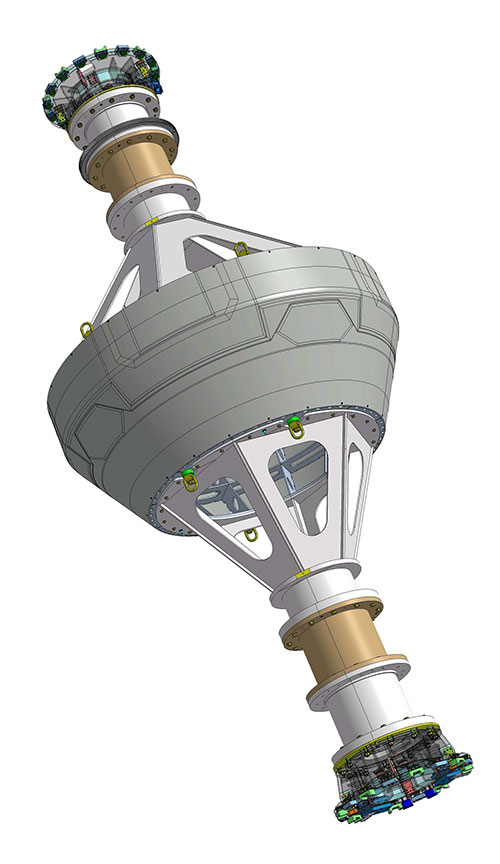

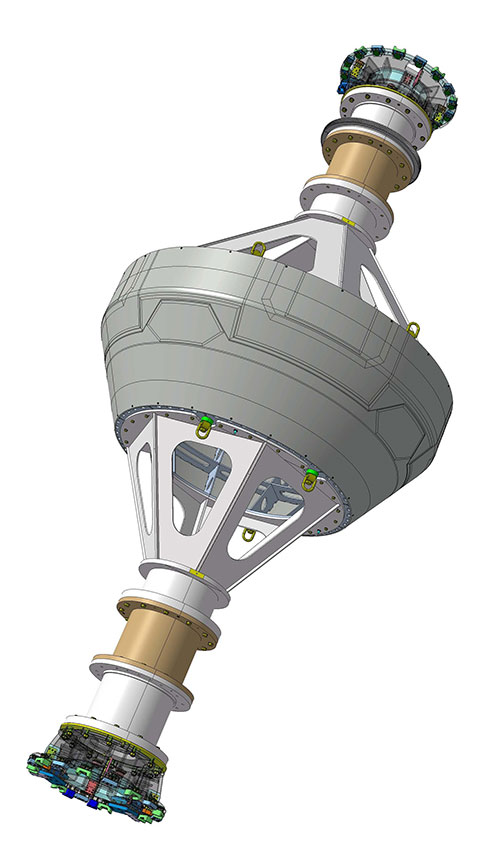

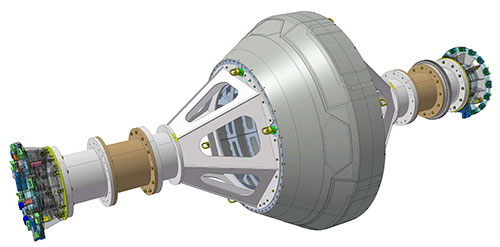

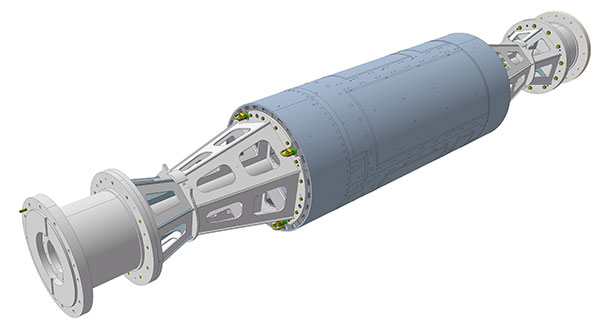

Design of barrel tooling in both steel and aluminum for the manufacture of revolution sections for both aircraft and satellites. These tools are placed using point and tailpoint in an automatic taping machine, and they are rotated to carry out the laminating process. Once the laminate is finished, the tooling is supported on a mobile support and placed in an autoclave to cure the section.

The key to success

These slender tools, supported only at the ends, must have an adequate balance between weight and structural rigidity in order to meet the strict deformation tolerances required by aeronautical manufacturers. The success of the development lies in a combination of iterations between design and structural calculation by finite elements until the optimal weight/stiffness balance is achieved.

How we achieve this

1

Design aimed at obtaining maximum flexural-torsion rigidity with the minimum possible weight.

2

Design aimed at quick assembly and disassembly on the machine.

3

Design oriented towards error-proof assembly (inclusion of poka yokes).

4

Manufacturing-oriented design.

5

Design aimed at interoperability between automatic taping machines with different point-counterpoint distances.

Financiado por la Unión Europea - NextGenerationEU