T100 WIND TURBINE

Description

100kW turbine for distributed generation and electrical self-consumption developed entirely by Argolabe; design, calculation, manufacturing management, assembly and commissioning carried out by Argolabe.

Argolabe has been a pioneer in the field of distributed electricity generation by fully developing a 100 kW wind turbine oriented for electrical self-consumption applications.

The key to success

With this wind turbine, energy can be generated next to the point of consumption, eliminating energy losses due to transportation and transformation, and taking advantage of a local, free and inexhaustible energy resource such as wind. The result is a more competitive system on an economic level and more efficient on a technical level with the following advantages:

- Electric bill reduction

- Increased network reliability; improvement of power quality and reduction of the number of interruptions in weak networks and line ends.

- Efficient use of energy by eliminating transport and transformation losses.

- Reduction of polluting emissions through the use of renewable energy.

How we achieve this

In 2009, the prototype unit was installed in the Álava technology park, and in 2012 the first series unit was installed, which supplies 100% of the electrical consumption of a winery in Rioja Alavesa, pouring the surpluses produced into the general network.

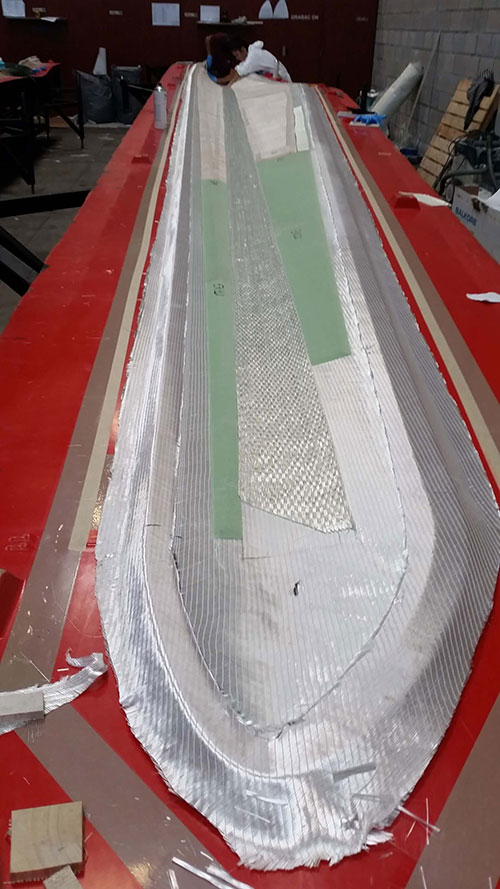

This development framed in R&D has been carried out from a multidisciplinary approach, with the Argolabe technical office assuming all its phases, from the mechanical and electrical design, through structural calculation, manufacturing management, assembly and startup. Furthermore, the manufacturing of components has been carried out with trusted local suppliers, which has an impact on the high final quality of the product.

1

Control of the entire process, from conceptual design to commissioning.

2

Exhaustive compliance with all IEC regulations related to wind turbine design.

3

Mathematical modeling of the wind turbine and aeroelastic simulations with high correlation with reality.

4

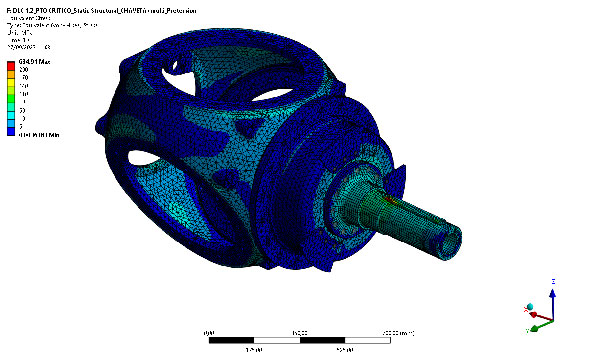

Fatigue and ultimate resistance calculation of all structural components to optimize weights and costs, and to select the most appropriate materials for each component.

5

Development of advanced nonlinear control systems.

6

Use of local suppliers to improve final product quality, optimize delivery times and ensure production conformity.

Financiado por la Unión Europea - NextGenerationEU